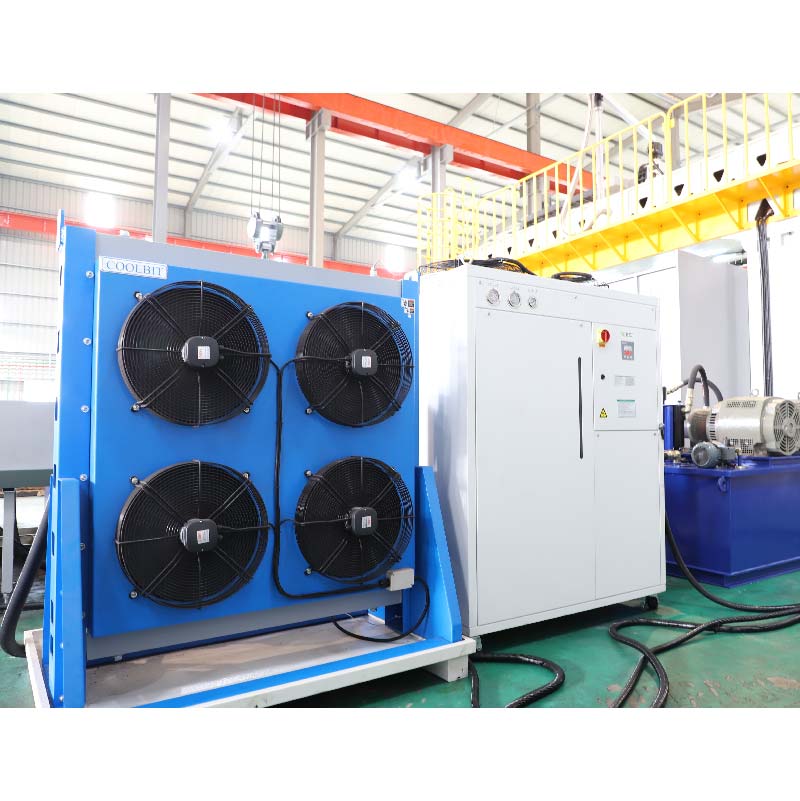

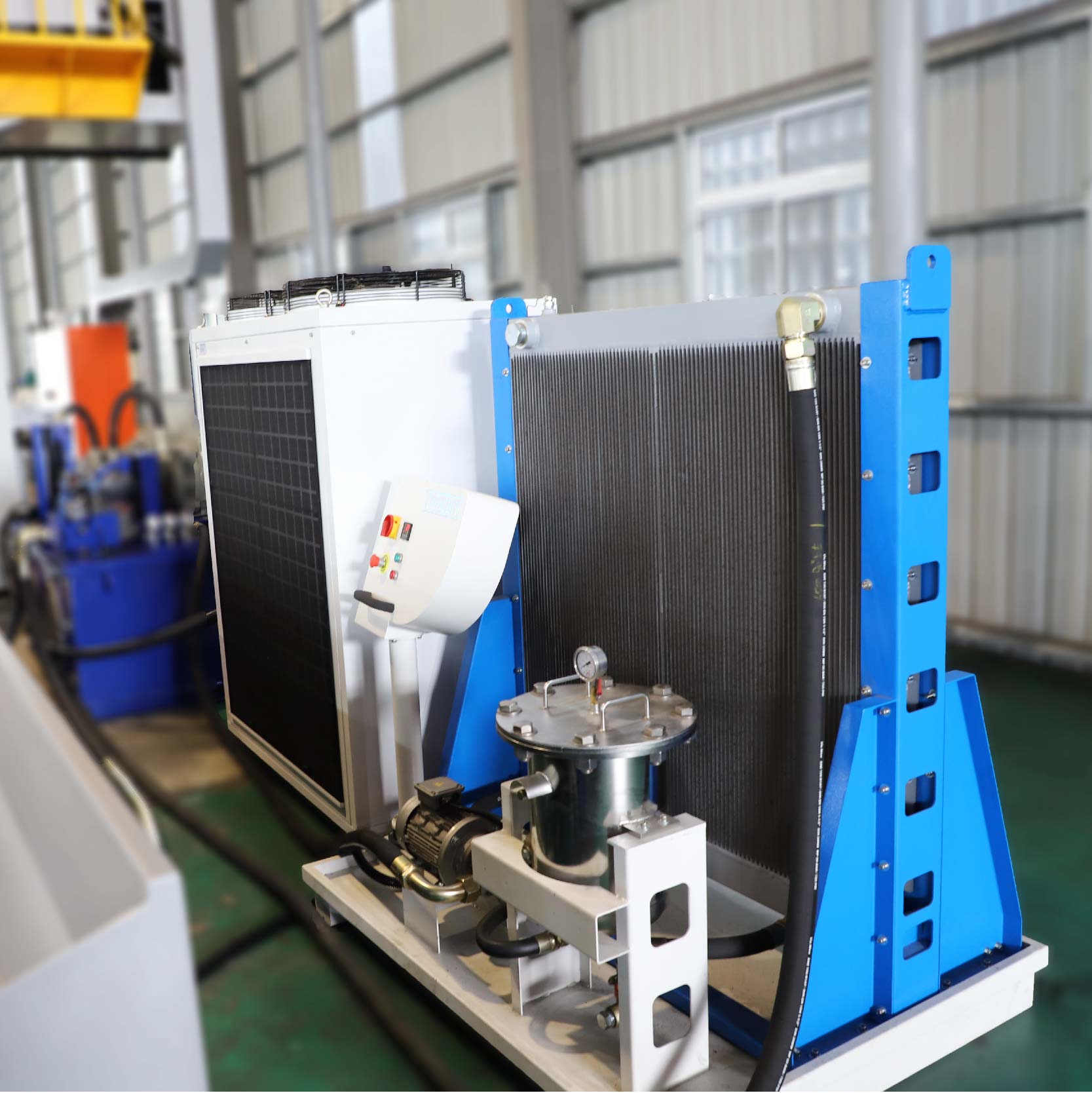

COOLBIT's Offline Heat Exchanger for Energy-Efficient Cooling in Metal Grinding and Processing Indus

Issue: Our client, a leader in the metal grinding and processing industry, sought an energy-efficient cooling solution for their gantry milling machines to reduce electricity costs. The machines generated significant heat during operation, requiring an effective cooling method without compromising performance.

Solution: COOLBIT's Offline Heat Exchanger technology was selected as the ideal solution for their cooling needs. This innovative system offered superior energy efficiency and optimal performance.

Results:

1. Remarkable Energy Savings: By adopting COOLBIT's Offline Heat Exchanger technology, they achieved exceptional energy savings. The system efficiently captured and dissipated heat, resulting in a significant 90% reduction in electricity costs associated with cooling.

2. Enhanced Equipment Performance: The Offline Heat Exchanger system maintained optimal operating temperatures for the gantry milling machines, preventing overheating and ensuring consistent performance. This contributed to increased equipment reliability, minimizing the risk of breakdowns and downtime.

3. Environmental Sustainability: Our client implementation of COOLBIT's energy-efficient cooling solution aligned with their commitment to environmental sustainability. The substantial reduction in electricity consumption significantly reduced their carbon footprint and supported their overall green initiatives.

4. Cost Savings and ROI: The substantial decrease in electricity costs had a positive impact on our client's financials. The investment in COOLBIT's energy-saving technology provided a favorable return on investment (ROI), contributing to the company's profitability.

Solution: COOLBIT's Offline Heat Exchanger technology was selected as the ideal solution for their cooling needs. This innovative system offered superior energy efficiency and optimal performance.

Results:

1. Remarkable Energy Savings: By adopting COOLBIT's Offline Heat Exchanger technology, they achieved exceptional energy savings. The system efficiently captured and dissipated heat, resulting in a significant 90% reduction in electricity costs associated with cooling.

2. Enhanced Equipment Performance: The Offline Heat Exchanger system maintained optimal operating temperatures for the gantry milling machines, preventing overheating and ensuring consistent performance. This contributed to increased equipment reliability, minimizing the risk of breakdowns and downtime.

3. Environmental Sustainability: Our client implementation of COOLBIT's energy-efficient cooling solution aligned with their commitment to environmental sustainability. The substantial reduction in electricity consumption significantly reduced their carbon footprint and supported their overall green initiatives.

4. Cost Savings and ROI: The substantial decrease in electricity costs had a positive impact on our client's financials. The investment in COOLBIT's energy-saving technology provided a favorable return on investment (ROI), contributing to the company's profitability.