Transitioning from Water Coolers to Air Coolers for Mechanical Press Cooling

Issue: A manufacturing company specializing in metal fabrication, was using water coolers to maintain optimal operating temperatures for their mechanical presses. However, they recognized the need to adopt a more eco-friendly and sustainable cooling solution that would reduce water consumption and environmental impact.

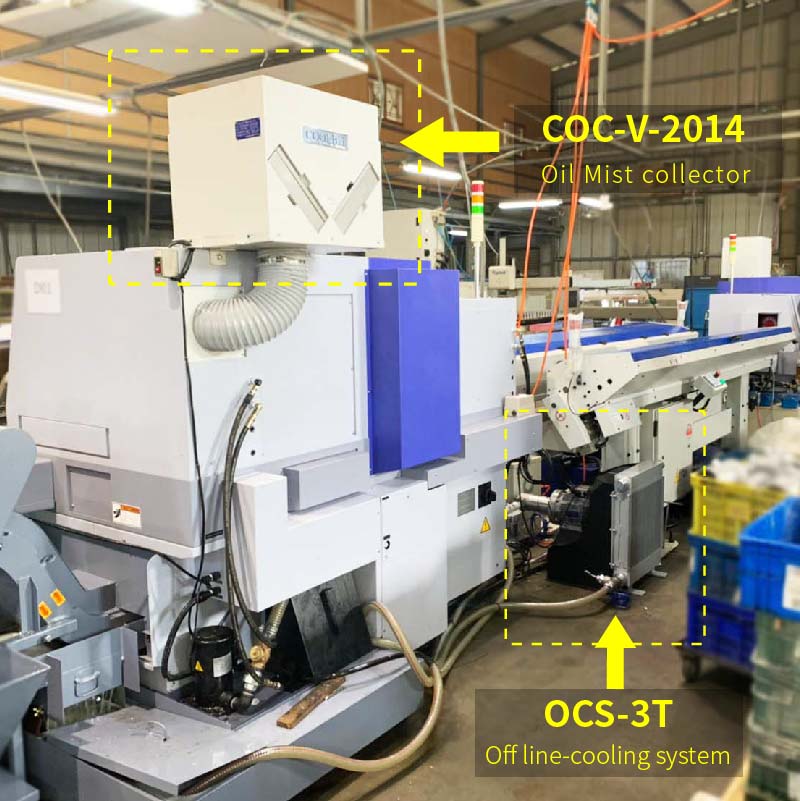

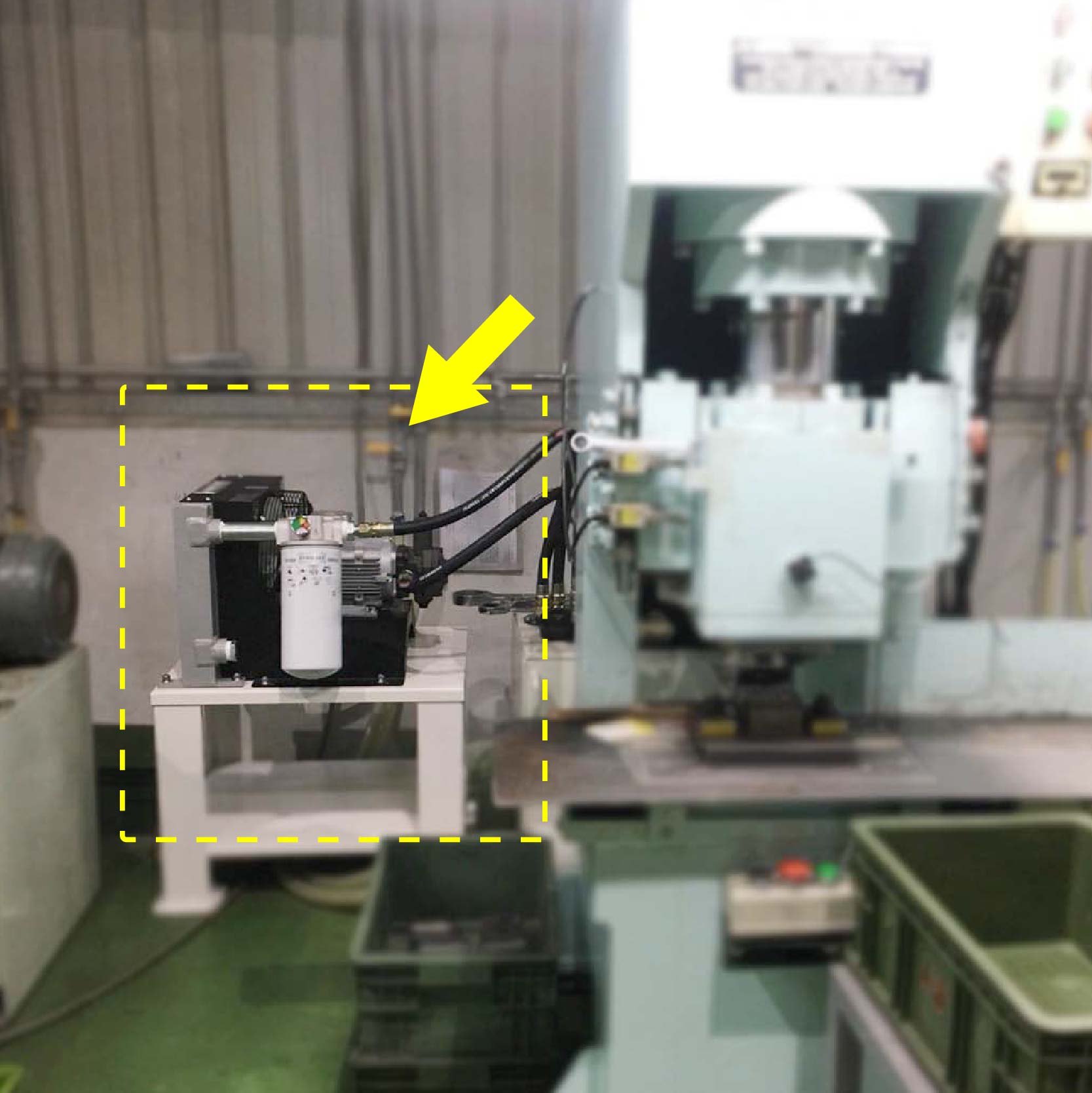

Solution: COOLBIT proposed the transition from water coolers to air coolers as an eco-friendly alternative for cooling the mechanical presses. The air coolers utilized advanced cooling technology that efficiently dissipated heat generated during the press operation.

Results:

1. Reduced Water Consumption: By replacing water coolers with air coolers, our client significantly reduced water consumption associated with press cooling. This not only helped conserve water resources but also eliminated the need for water treatment and associated costs.

2. Energy Efficiency: The air coolers implemented by COOLBIT were designed to optimize energy usage and minimize power consumption. Our client observed a noticeable reduction in energy requirements for press cooling, leading to cost savings and lower environmental impact.

3. Enhanced Productivity and Reliability: The transition to air coolers improved the cooling efficiency of the mechanical presses, resulting in more stable operating temperatures. This led to enhanced productivity, reduced downtime due to overheating, and improved overall equipment reliability.

4. Environmental Sustainability: By adopting the eco-friendly air cooling solution, our client demonstrated its commitment to environmental sustainability. The reduction in water consumption and energy usage contributed to their overall green initiatives and positioned them as a responsible and eco-conscious manufacturer.

Solution: COOLBIT proposed the transition from water coolers to air coolers as an eco-friendly alternative for cooling the mechanical presses. The air coolers utilized advanced cooling technology that efficiently dissipated heat generated during the press operation.

Results:

1. Reduced Water Consumption: By replacing water coolers with air coolers, our client significantly reduced water consumption associated with press cooling. This not only helped conserve water resources but also eliminated the need for water treatment and associated costs.

2. Energy Efficiency: The air coolers implemented by COOLBIT were designed to optimize energy usage and minimize power consumption. Our client observed a noticeable reduction in energy requirements for press cooling, leading to cost savings and lower environmental impact.

3. Enhanced Productivity and Reliability: The transition to air coolers improved the cooling efficiency of the mechanical presses, resulting in more stable operating temperatures. This led to enhanced productivity, reduced downtime due to overheating, and improved overall equipment reliability.

4. Environmental Sustainability: By adopting the eco-friendly air cooling solution, our client demonstrated its commitment to environmental sustainability. The reduction in water consumption and energy usage contributed to their overall green initiatives and positioned them as a responsible and eco-conscious manufacturer.